ACRYLIC & METHACRYLIC RESINS

Main advantages of organic peroxides:

- Productivity: a broad half-life range for various temperature profiles.

- Quality: low residual monomer and low color solutions.

- Handling: peroxides are mostly organic liquids, which means fast and complete solubility.

Peroxide Selection Guidelines: Solvant & Aqueous based coating resins – PMMA resins – Grafted Polymers

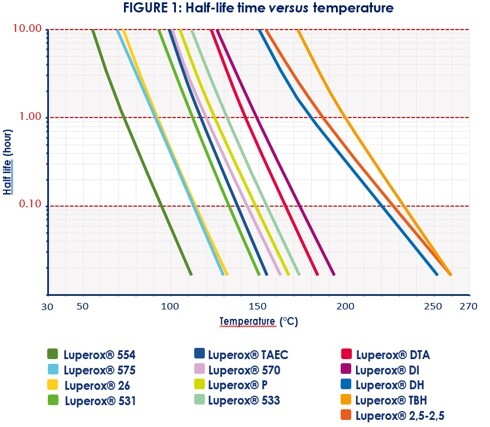

Figure 1 shows a selection of organic peroxides than can be used depending on the polymerization temperature.

Proper initiator selection can result in a better control of the molecular weight of the resin, a decrease of polydispersity and an increase of the level of solids in the formulation.

Luperox® 26 and Luperox® DI are the most common for standard products, whereas specialty products used Luperox® 531, Luperox® 575, Luperox® 533 or Luperox® DTA.

Tertio-amyl proxides benefits for solvent based acrylic resins

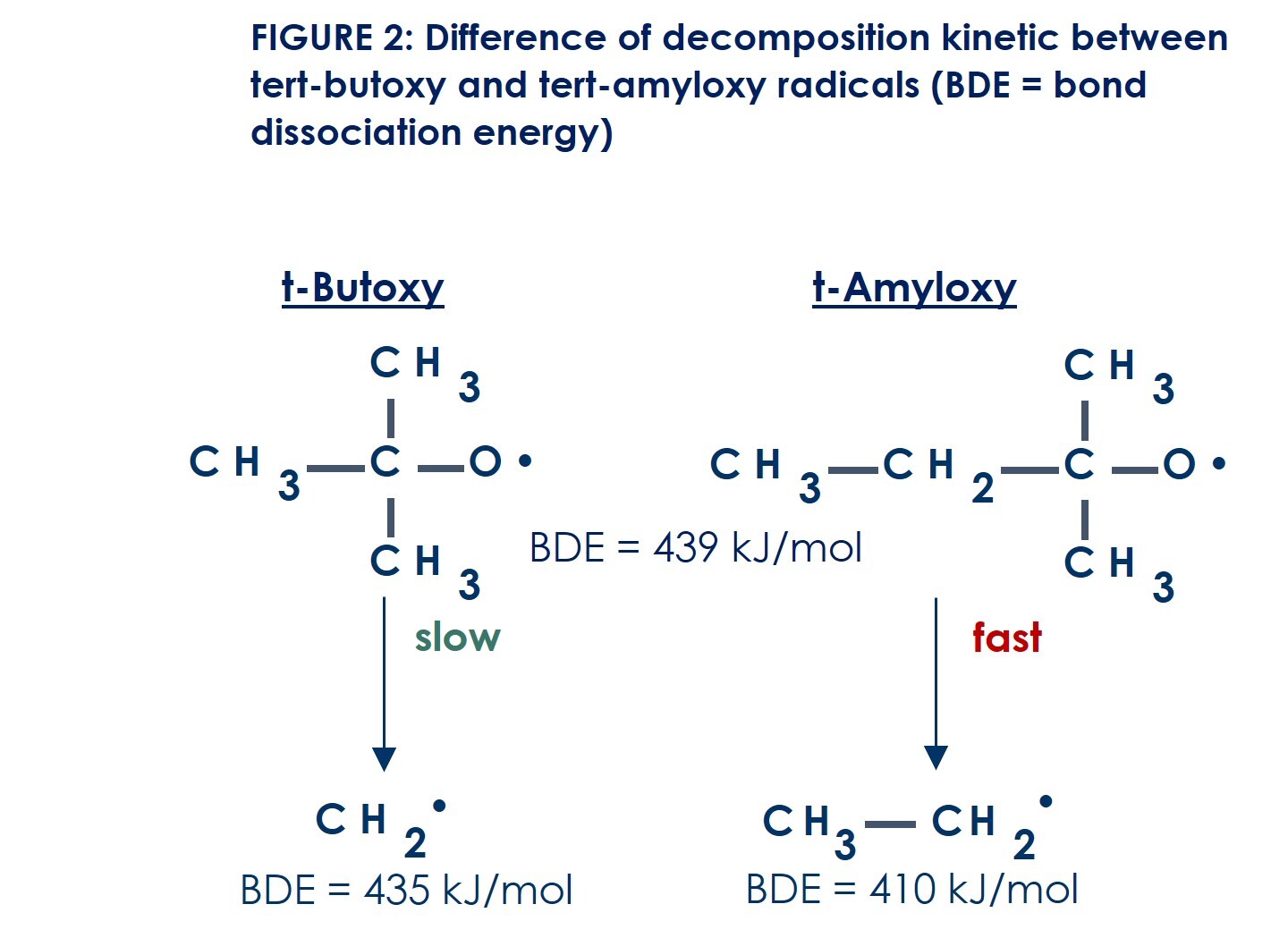

Tert-amyl peroxides Luperox® 533, Luperox® 570, Luperox® 531, Luperox® 575 or Luperox® DTA give radicals with lower energy, avoiding risks of hydrogen abstraction and favoring polymerization, see figure 2.

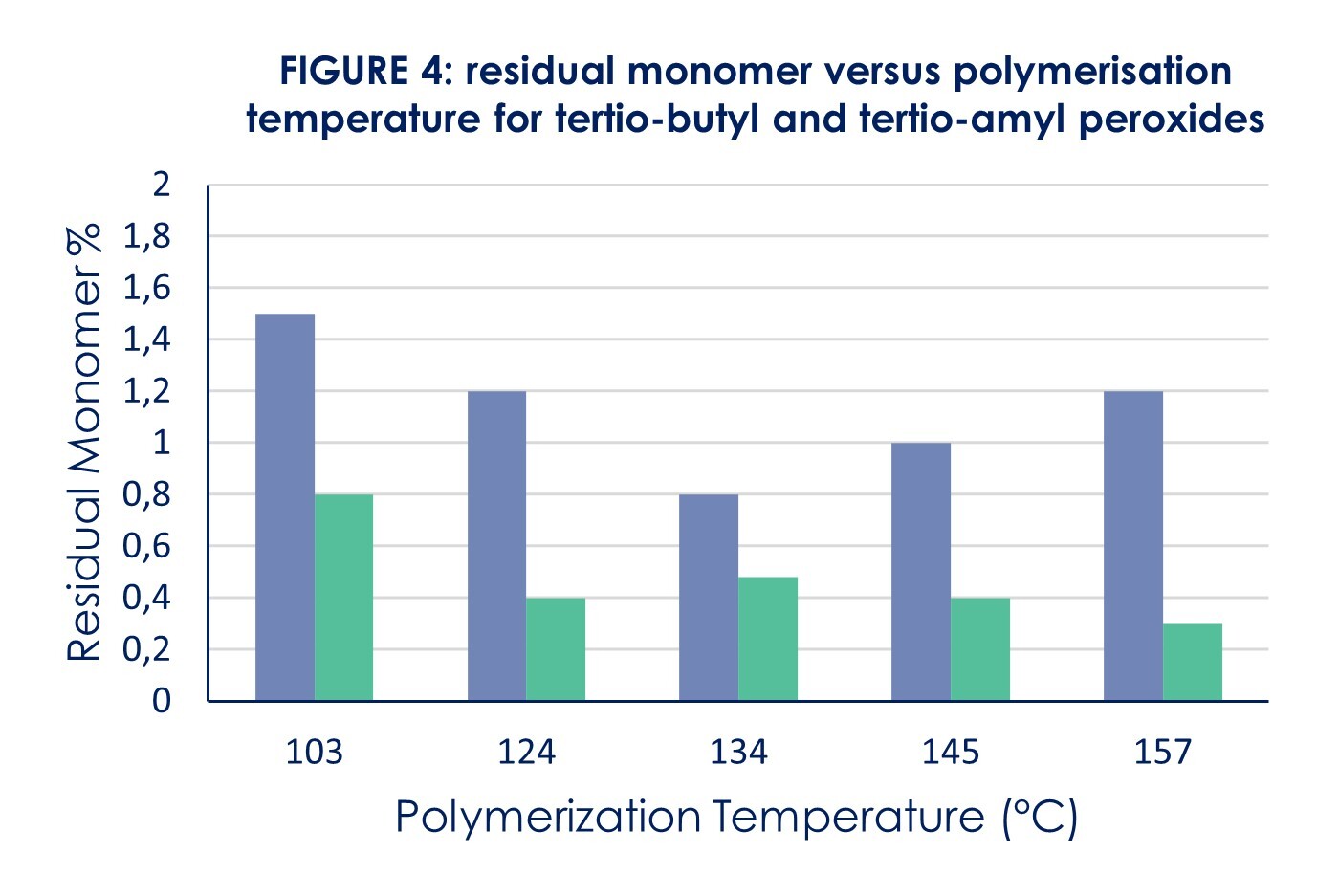

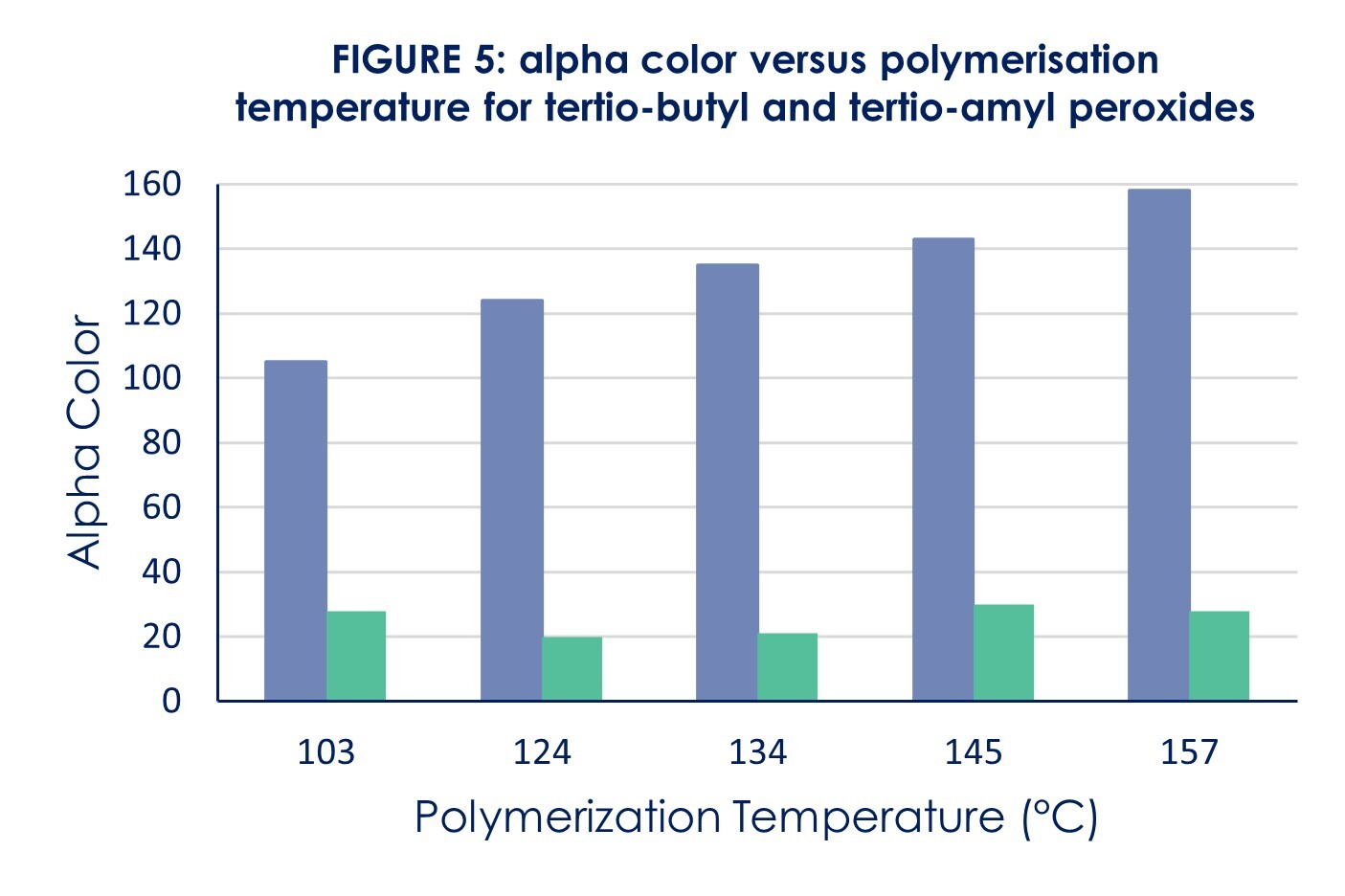

These radicals are more selective, which means higher output, see figure 3, 4 and 5.

In conclusion, the use of tert-amyl peroxides may contribute to:

- A lower solution viscosity

- A narrower molecular weight distribution

- A lower quantity of volatile organic residuals

- A higher solid resin content

- An improvement in color.

FIGURE 3: Comparison on molecular weight, distribution and viscosity

|

Organic Peroxide |

Half life temperature at 1h (°C ) |

Mn (g/mol) |

MW/Mn |

Viscosity (poise) |

|---|---|---|---|---|

|

Luperox® DTA |

143 |

2500 |

1.81 |

15 |

|

Luperox® DI |

149 | 3200 |

2.60 |

32 |

|

Luperox® 533 |

132 |

2800 |

2.00 |

25 |

|

Luperox® 233 |

130 | 3700 |

2.30 |

52 |

|

Luperox® 570 |

120 | 3300 |

1.90 |

38 |

|

Luperox® 270 |

123 | 3600 | 2.25 | 51 |

|

Luperox® 531 |

112 | 4600 | 2.41 | 93 |

|

Luperox® 231 |

112 | 5300 |

3.20 |

152 |

|

Luperox® 575 |

91 | 6400 |

2.09 |

152 |

|

Luperox® 26 |

92 | 7200 |

2.49 |

188 |

Hydroxyperoxides for aqueous based acrylic resins

For the polymerization of acrylic resins in aqueous phase, Arkema can supply various water soluble hydroperoxides like Luperox® TBH70X in water or Luperox® DH in Diisopropylbenzene.

Hydroperoxides are used in acrylics polymerization in presence of a suitable reducing agent to initiate the polymerization at low temperature. Hydroperoxides can be used as initiator as well as chasers and are very efficient in the reduction of residual monomer.

PMMA resins

PMMA is mainly produced by mass or suspension free radical polymerization.

The suspension process is a batch process at 80-100°C, in which methylmethacrylate is polymerized in the presence of non-water-soluble peroxide like Luperox® LP, Luperox® 26 or Luperox® 575.

The mass process is generally conducted at higher temperature such as 120-130°C or even higher thereby requesting efficient free radicals with a higher half-life temperature like Luperox® 231, Luperox® 331 or Luperox® 531.

Grafted Polymer Polyol (SAN-Polyether Polyol Copolymers)

Polymer polyols are made by copolymerizing styrene and acrylonitrile in the presence of polyether polyols. Free radicals obtained from the thermal decomposition of tertio-amyls peroxides such as Luperox® 575, Luperox® 554M75, Luperox® 531M60 or Luperox® POP2 are lower in energy and thus do not really abstract hydrogen from polymer backbones.

This is desirable in polymer-polyol synthesis to maintain polyol integrity during controlled styrene/acrylonitrile grafting, thereby achieving low viscosity and narrow molecular weight distributions. It is also possible to reduce the monomer stripping operations by using a select blend of t-amyl peroxides as chasers.